Fruit vinegar

Acetic fermentation

Cotton Wool

Air Tube (4)

Filled to the Halfway Point (2)

Support Rack (3)

Tap

Ground Cob Maize (1)

Practical Action

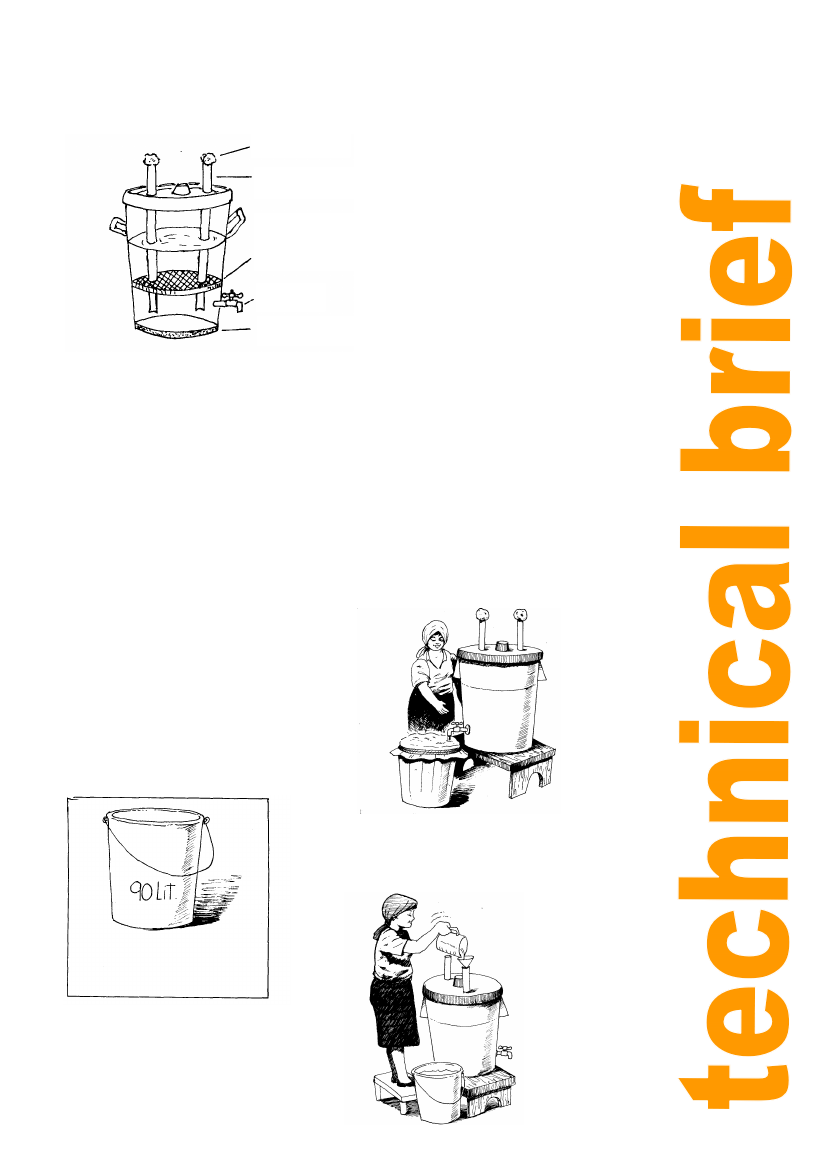

Fermentation equipment

First, the acetic fermentation equipment must be got ready. This must have a thin layer of ground

maize cobs at the bottom of the container (1). It is then filled with the prepared alcoholic must to

the 160 litre mark when using a 250 litre vessel. The support grille (3) is then put in place. This

grille is made from a ring of non-resinous wood with the central part covered with nylon mesh.

Plastic tubes (4) pass through the cover and the support grille. These are needed to supply air to

the must.

The initial acetic fermentation takes 60 days. After about 18 days, a whitish layer or skin appears

on the surface or on the wooden support. From this moment the acidity begins to increase reaching

approximately 5% acetic acid during the remaining days.

Obtaining the vinegar

After the required number of days of acetic

fermentation and the white layer has formed

on the surface; as a thickish gelatinous skin;

the vinegar reaches 5% acidity. The next

steps are to:

1: Separate 20 litres of vinegar with

approximately 5% acetic acidity into a

container.

2: Add 100 litres more of prepared alcoholic must to the

remaining 70 litres of vinegar.

How do we obtain this prepared alcohol must?

6